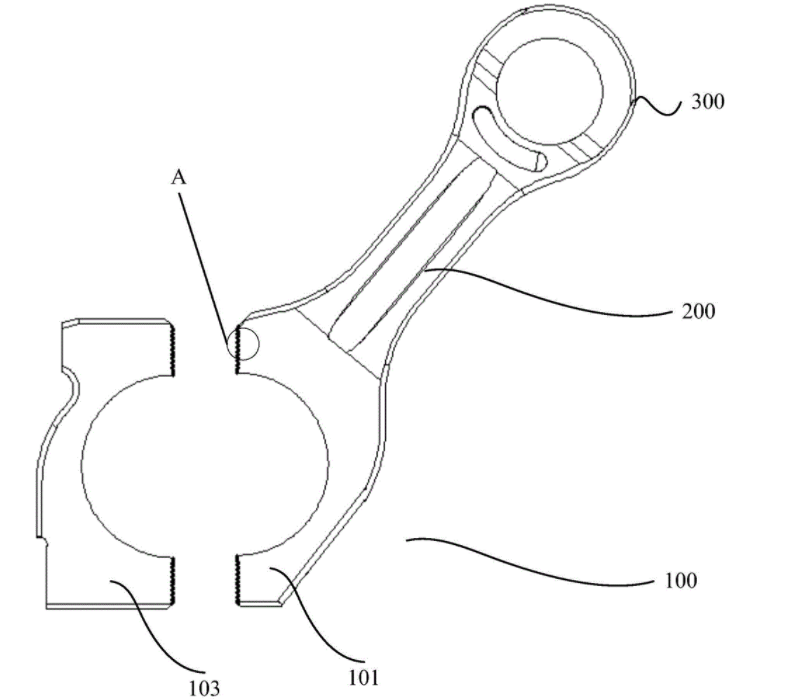

The connecting rod, often abbreviated as conrod, is a pivotal component in most internal combustion engines. It serves as the crucial link between the piston and the crankshaft, converting reciprocating motion into rotary motion. This transfer of energy is what ultimately propels an automobile forward. Understanding the various parts of a connecting rod and their individual functions can provide a deeper insight into the inner workings of an engine.

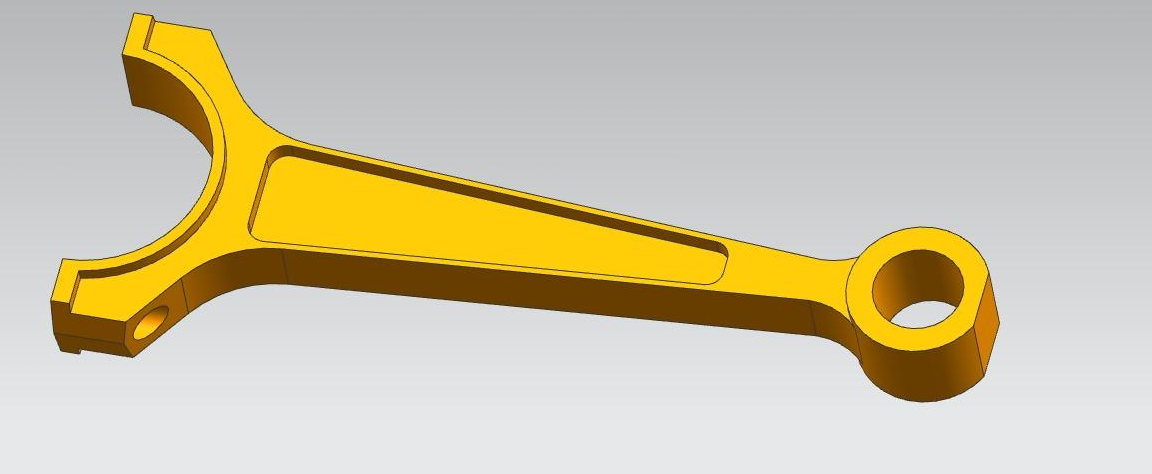

The body of the connecting rod, also known as the rod beam, is the core component providing the main structure. This part needs to be extremely robust as it bears the primary tensile and compressive forces during the engine’s operation.

On each end of the rod body, there are the small end and the big end. The small end attaches to the piston through the piston pin, while the big end connects to the crankshaft at the crankpin. The big end typically comes with a two-piece design for assembly and disassembly around the crankpin.

Bushings are often incorporated at both ends of the connecting rod. These are typically made of bronze, serving to reduce friction and wear during the operation.

Bearing shells are another crucial component found in the big end of the connecting rod. These shells, made of materials with excellent anti-friction properties, reduce friction between the connecting rod and the crankpin.

Keeping the big end securely fastened around the crankpin are bolts and nuts. These small but mighty components are engineered to endure the high stresses and strains experienced during the engine operation.

Equally important are the lubrication ports. These channels allow oil to flow to the critical areas of the connecting rod, reducing friction and heat.

The connecting rod cap and cap screws work together to form part of the big end that encloses the crankpin. The cap is usually bolted to the connecting rod body using the cap screws, which are designed to withstand high forces and temperatures.

Dowel pins also play an essential role in maintaining the structural integrity of the connecting rod. They align the cap and rod body correctly during assembly.

The parting line, the junction where the rod body and cap meet, is critical for maintaining the alignment and balance of the connecting rod.

A lot of science and engineering go into the design of a connecting rod, including its length and weight, beam design, and choice of materials. All these factors need to be balanced to optimize the engine’s performance and efficiency.

Further, advancements in technology have brought forth innovations in conrod design and manufacturing techniques. Heat treatment processes, surface coatings, and strict inspection protocols ensure the production of durable and reliable connecting rods.

Regular maintenance and replacement of worn-out components are key to the longevity and performance of connecting rods.

Lastly, as we look towards the future, we can expect continuous improvements in the design, materials, and manufacturing processes of connecting rod parts. These advancements will result in more efficient, reliable, and environmentally friendly engines, keeping pace with the ever-evolving demands of the automotive industry.

Introduction

An overview of the importance of connecting rods in engine operation and the role of its individual components.

The Body of the Connecting Rod

A look into the rod beam, which bears the primary tensile and compressive forces during the engine’s operation.

The Small End and Big End

An examination of the small and big ends of the connecting rod and their connections to the piston and crankshaft, respectively.

The Role of Bushings

A discussion on the importance of bushings in reducing friction and wear in the connecting rod.

The Function of Bearing Shells

An exploration of bearing shells and how they reduce friction between the connecting rod and the crankpin.

Bolts and Nuts: Holding It All Together

An overview of how bolts and nuts secure the big end of the connecting rod around the crankpin.

The Role of Lubrication Ports

A discussion about lubrication ports and their importance in reducing friction and heat in the connecting rod.

The Importance of the Connecting Rod Cap and Cap Screws

An examination of the connecting rod cap and cap screws, which form part of the big end that encloses the crankpin.

The Significance of Dowel Pins

A look at the role of dowel pins in maintaining the structural integrity of the connecting rod during assembly.

Understanding the Parting Line

An explanation of the parting line and its importance in maintaining the alignment and balance of the connecting rod.

The Science Behind Conrod Design

An in-depth exploration of the considerations that go into designing a connecting rod.

Length and Weight Considerations

A discussion on the impact of length and weight on the performance and efficiency of an engine.

Beam Design

A comparison of different beam designs and their implications on the strength and stiffness of the connecting rod.

Material Selection

An overview of the materials commonly used in connecting rod construction and their respective properties.

Manufacturing Techniques for Conrods

A look at various manufacturing techniques used in conrod production.

Heat Treatment

A discussion on the benefits of heat treatment processes in enhancing the strength and durability of connecting rods.

Surface Coatings

An exploration of different types of surface coatings and how they improve the lifespan and performance of conrods.

Inspection and Quality Control

An overview of the importance of regular inspection and strict quality control in ensuring the reliability of connecting rods.

Maintenance and Replacement of Conrods

A discussion on the importance of proper maintenance and timely replacement of worn-out connecting rod components.

Conrod Innovations and Future Trends

A look at the latest advancements in conrod design and what the future holds for this critical engine component.

Concluding Thoughts

A summary of key points discussed in the article and reflections on the future of connecting rod design and manufacturing.