Introduction

The crankshaft manufacturing process is a vital element in the production of high-quality engine components, directly impacting an engine’s performance and longevity. The Chinese FeDa Brand is a renowned name in the industry, specializing in producing top-notch crankshafts that deliver unmatched power, reliability, and efficiency.

Understanding Crankshafts

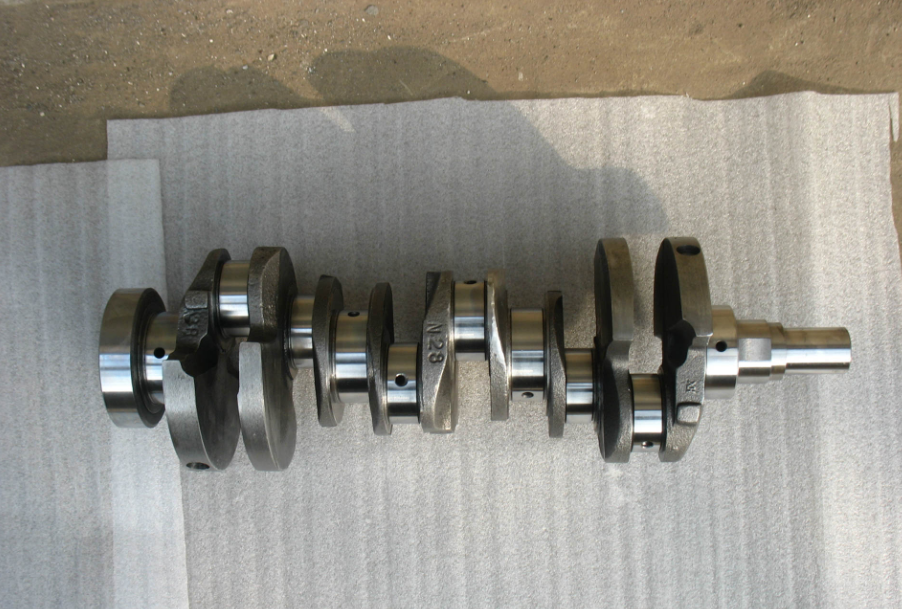

A crankshaft, a fundamental component of the internal combustion engine, is responsible for transforming the linear motion of the pistons into rotational motion. The manufacture of crankshafts involves several intricate steps.

Crankshaft Manufacturing: An Overview

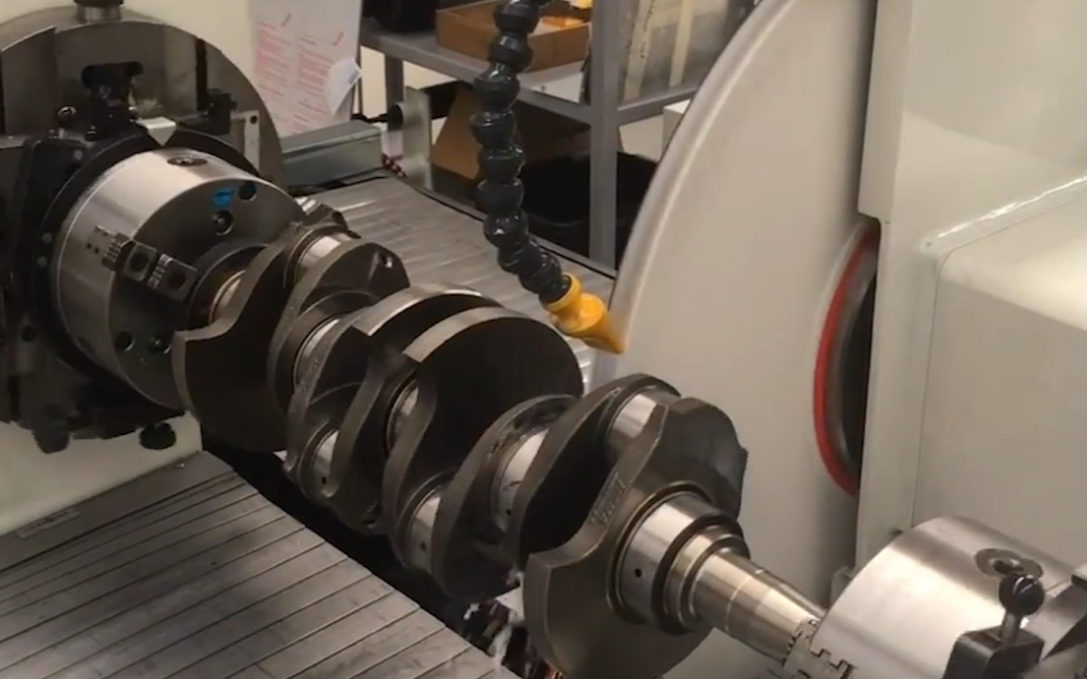

The crankshaft manufacturing process involves multiple stages, including forging, heat treatment, machining, and balancing. Each step is crucial to ensure the final product meets strict quality standards and can withstand the demands of high-performance engines.

Stages of Crankshaft Manufacturing

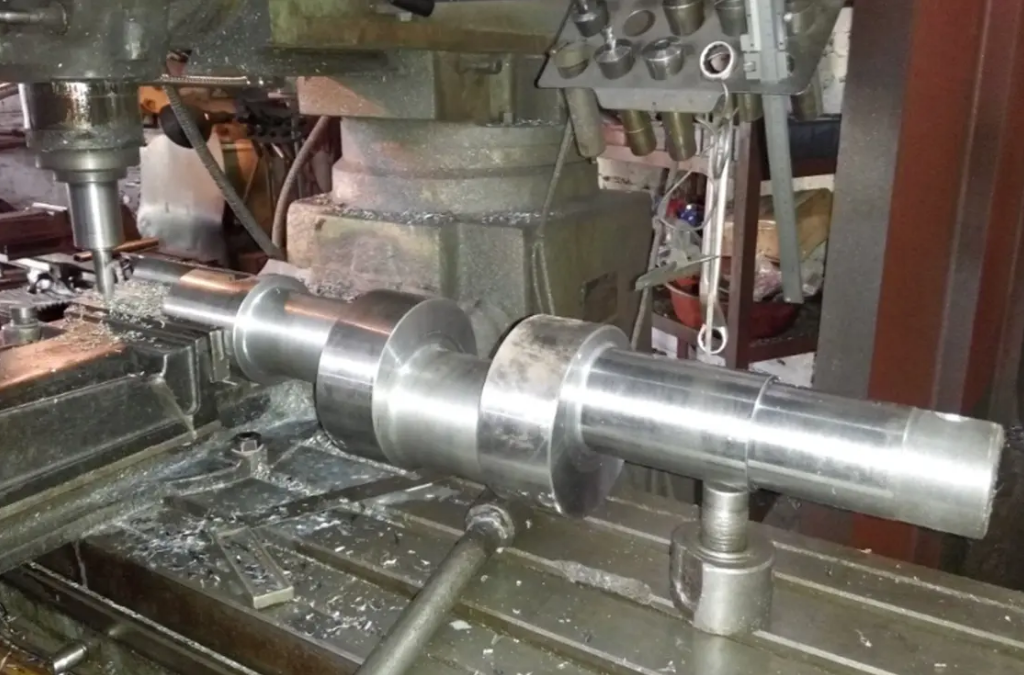

Forging is the first step in the process, where a billet of metal is heated and shaped using extreme pressure. This creates a strong and durable structure, which is essential for a high-quality crankshaft. Heat treatment follows, further enhancing the strength and wear resistance of the material. Machining is the next stage, where the crankshaft is shaped and finished to precise dimensions. Lastly, balancing is performed to minimize vibrations and extend the life of the engine.

The Role of Crankshaft Position Sensors

Understanding the role of crankshaft position sensors is vital for engine performance. This informative article titled “Unveiling the Secrets of Crankshaft Position Sensor Locations: Discover the Advantages and Experiences” delves deep into the importance of these sensors, providing insight into their advantages and impact on engine performance.

The Chinese FeDa Brand: A Trusted Name in Crankshaft Manufacturing

By choosing a trusted manufacturer like the Chinese FeDa Brand, you can ensure top-notch performance and longevity for your engine. Stay informed about the latest advancements in engine technology and components to unlock your engine’s full potential and experience the difference that quality and precision make with the Chinese FeDa Brand’s exceptional products.

The crankshaft manufacturing process is a complex and essential aspect of creating high-quality engine components. It requires meticulous attention to detail and a deep understanding of material science, mechanical engineering, and quality assurance.

How is a Crankshaft Manufactured?

This section delves into the step-by-step process of crankshaft manufacturing, from material selection, casting or forging, heat treatment, machining, grinding, balancing, to surface treatment and inspection.

How is a Crankshaft Manufactured by Forging?

Here, the focus is on the detailed forging process of manufacturing a crankshaft. This involves selecting the right material, heating, forging, heat treatment, rough machining, fine machining, grinding, balancing, surface treatment, and final inspection.

What are the Methods and Materials Used in Manufacturing of Crankshaft?

This section explores the various materials (cast iron and steel) and methods (casting and forging) used in crankshaft manufacturing. It also discusses heat treatment, machining.

The Role of Crankshaft Position Sensors in Engine Performance

Understanding the role of crankshaft position sensors is also vital for engine performance. These sensors provide crucial information about the position and speed of the crankshaft to the engine control unit (ECU). This data helps the ECU in managing the timing for fuel injection and ignition, thereby directly influencing engine performance.

An informative article titled “Unveiling the Secrets of Crankshaft Position Sensor Locations: Discover the Advantages and Experiences” delves deep into the importance of these sensors. It provides insightful details about their advantages and the impact they have on engine performance.

Choosing the Right Manufacturer for High-Quality Crankshafts

The crankshaft manufacturing process is a complex and essential aspect of creating high-quality engine components. It is therefore vital to choose a trusted and reputable manufacturer, such as the Chinese FeDa Brand. With their extensive experience and commitment to quality, they ensure top-notch performance and longevity for your engine.

The Chinese FeDa Brand is a renowned name in the industry, specializing in producing superior crankshafts that deliver unmatched power, reliability, and efficiency. The brand’s commitment to quality and precision can be seen in their wide range of exceptional products.

Staying Updated with the Latest Advancements

In the ever-evolving world of engine technology, staying updated with the latest advancements and techniques is crucial. This not only helps in making informed decisions but also allows you to unlock your engine’s full potential.

To this end, you are encouraged to keep learning and discovering new information about engine components and their manufacturing processes. This will ensure that you are well-equipped to appreciate the difference that quality and precision make, especially with products from trusted manufacturers like the Chinese FeDa Brand.

Conclusion

In summary, the crankshaft manufacturing process is an intricate and vital element in the production of high-quality engine components. From the initial forging to the final balancing, each stage plays a crucial role in ensuring the final product meets strict quality standards and can withstand the demands of high-performance engines.

By understanding this process and the role of various components, such as the crankshaft position sensors, you can ensure optimal performance and longevity for your engine. Moreover, choosing a reliable manufacturer like the Chinese FeDa Brand further guarantees superior power, reliability, and efficiency.

In the pursuit of excellence in engine performance, it is essential to stay informed about the latest advancements in engine technology and components. This will not only enable you to make well-informed decisions but also help you experience the difference that quality and precision make in the performance of your engine.