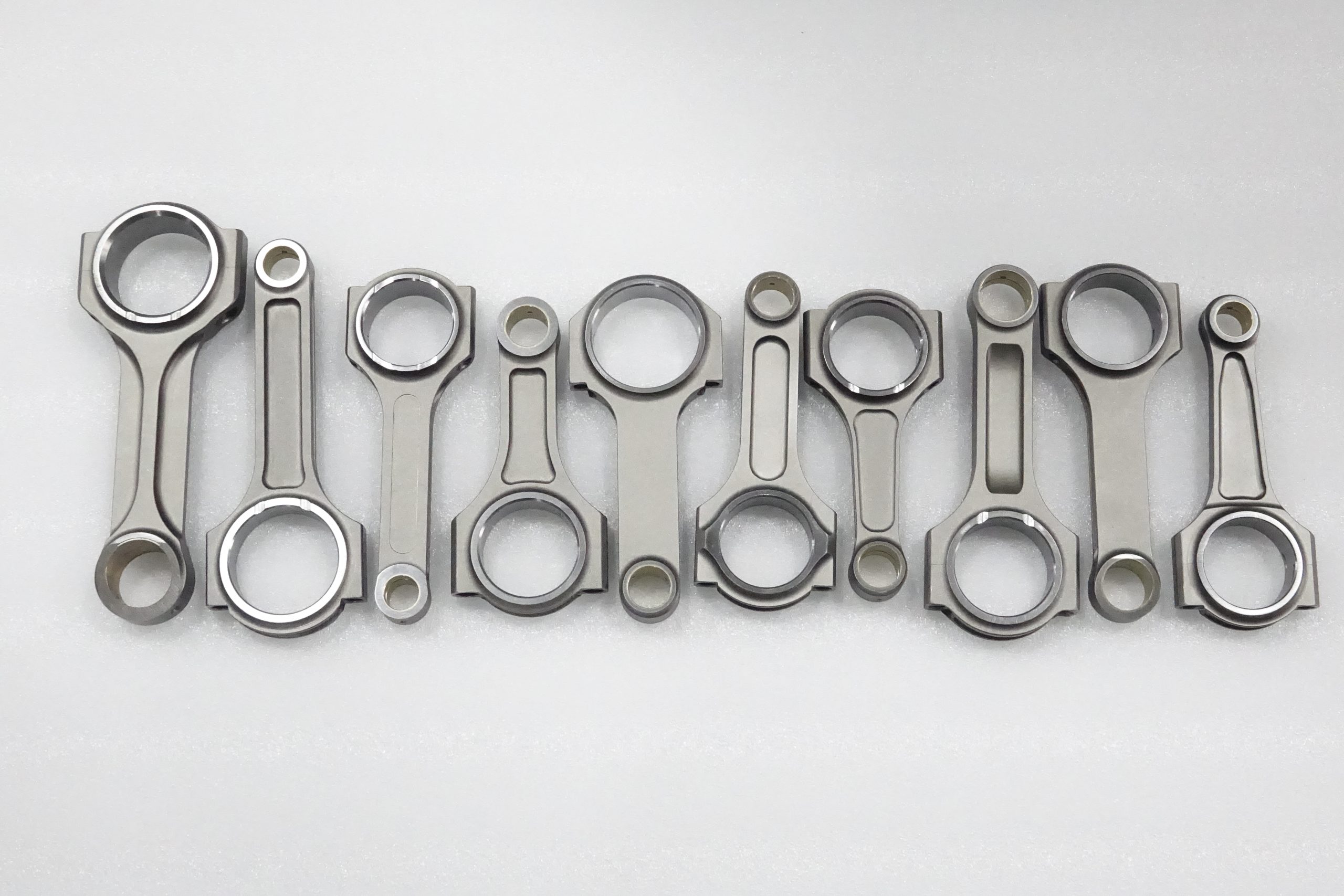

Transcend Energy Group Connecting Rod: Revolutionizing Engine Performance

Transcend Energy Group connecting rod has emerged as a game-changer in the realm of high-performance engines. This innovative product boasts cutting-edge design and advanced materials, resulting in an engine component that delivers superior performance, reliability, and efficiency. One of the most notable features of the Transcend Energy Group connecting rod is its use of high-quality materials. By employing aerospace-grade alloys and advanced manufacturing techniques, these connecting rods are built to withstand the extreme forces and temperatures found in high-performance engines. This results in a component that is both lightweight and incredibly strong, providing excellent durability and reliability. Optimized weight distribution is another key advantage of the Transcend Energy Group connecting rod. By carefully engineering the rod’s geometry, the designers have achieved a balance that minimizes rotational mass and maximizes engine efficiency. This can lead to smoother operation, improved throttle response, and increased horsepower and torque. The attention to detail in