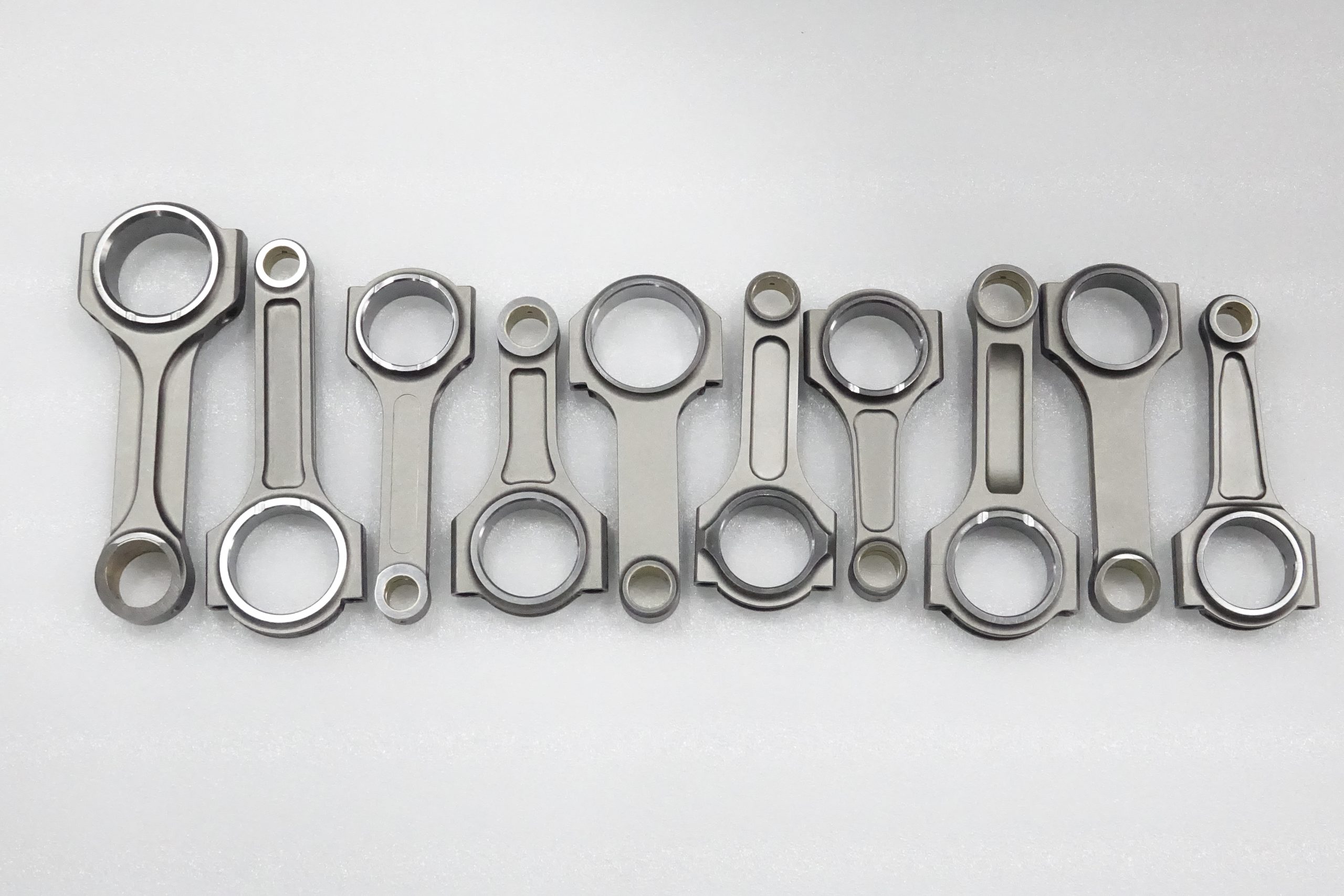

Forged Connecting Rod Manufacturing Process: A Comprehensive Overview aims to provide an in-depth look at the intricacies of creating high-performance forged connecting rods, which are essential components in the automotive and racing industries.

A connecting rod is a critical part of an internal combustion engine, linking the piston to the crankshaft and converting linear motion into rotational motion. Forged connecting rods offer superior strength and durability compared to other manufacturing methods. The forging process involves heating a piece of metal, usually steel, to a high temperature and then shaping it using force or pressure.

- Material selection: The first step in the forged connecting rod manufacturing process is to choose the appropriate material. High-quality steel, such as 4340 or 300M, is commonly used due to its excellent strength and toughness properties.

- Heating: The selected material is heated to a specific temperature, typically between 1,200 and 1,300 degrees Celsius. This heating process, known as austenitizing, softens the steel and prepares it for the forging process.

- Forging: Once heated, the steel is placed under a forging press or hammer, which applies pressure to shape the material into the desired connecting rod form. This process can be done through open-die or closed-die forging, depending on the required precision and complexity of the part.

- Heat treatment: After forging, the connecting rod undergoes heat treatment to improve its mechanical properties. This process typically involves quenching, which rapidly cools the part, followed by tempering at a lower temperature to achieve the desired balance of hardness and toughness.

- Machining: The heat-treated connecting rod is then machined to its final dimensions. This step often includes milling, turning, drilling, and grinding operations to achieve precise tolerances and surface finishes.

- Surface treatment: To further enhance the connecting rod’s performance, surface treatments such as shot peening or surface nitriding may be applied. These treatments can increase fatigue strength and wear resistance, leading to a longer-lasting part.

- Quality control and inspection: Throughout the manufacturing process, rigorous quality control measures are implemented to ensure the connecting rod meets the required specifications. Non-destructive testing methods, such as magnetic particle inspection or ultrasonic testing, may be employed to detect any potential defects or flaws in the part.

In conclusion, the forged connecting rod manufacturing process is a complex series of steps that result in a high-quality, high-performance component. By carefully selecting materials, applying precise forging techniques, and ensuring proper heat treatment and machining, manufacturers can create connecting rods that offer superior strength, durability, and performance.