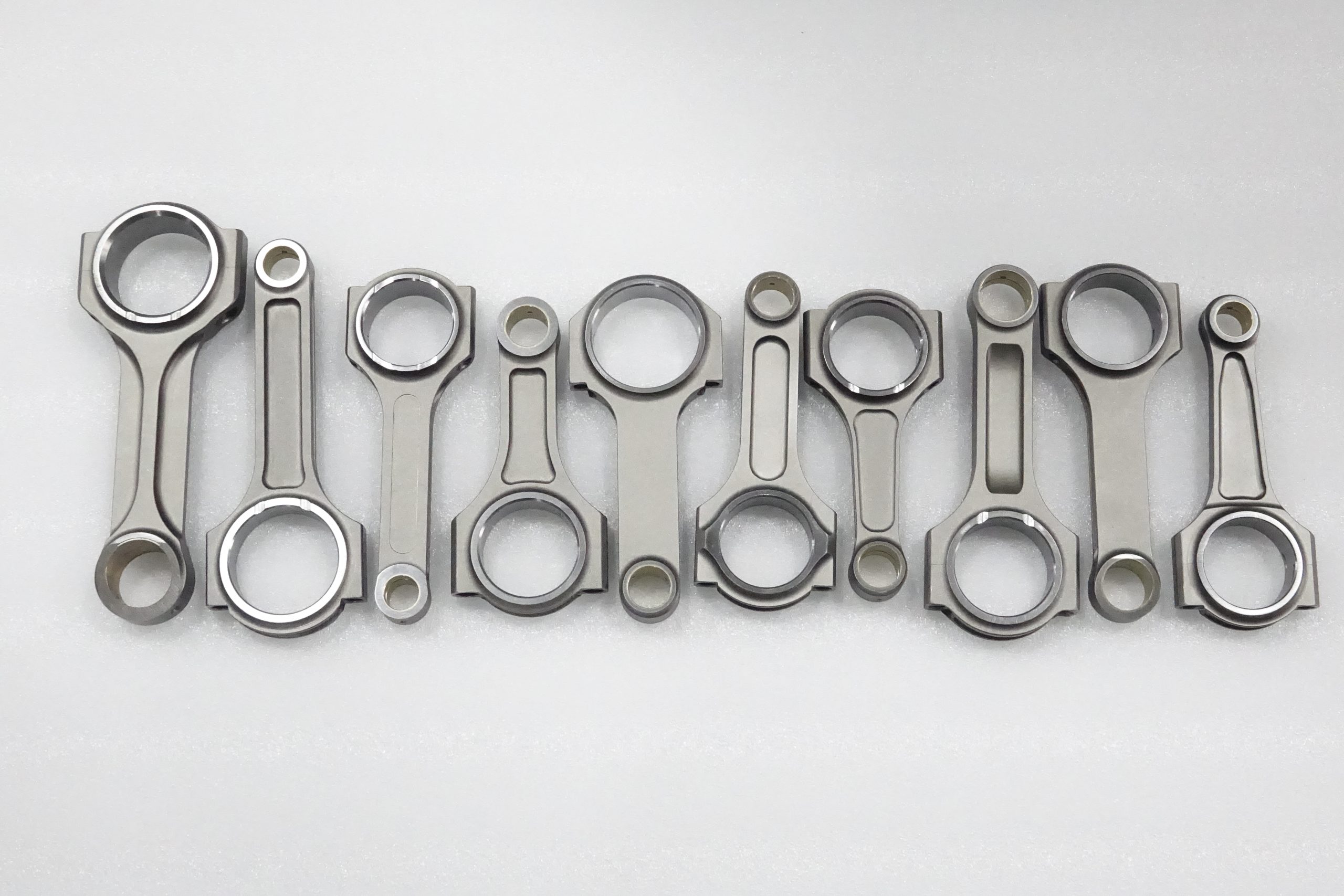

What are Connecting Rods? Unveiling the Unsung Heroes of Engine Performance

What are connecting rods? Many people who are passionate about automobiles or machinery may have heard the term but may not fully understand the vital role these components play in an engine’s operation. This article aims to shed light on the essential function and characteristics of connecting rods and why they are the unsung heroes of engine performance. At its core, a connecting rod is a crucial component in internal combustion engines, responsible for transferring the reciprocating motion of the pistons into the rotational motion of the crankshaft. In simpler terms, connecting rods are the bridge that allows the engine’s power to be converted into the force that propels a vehicle forward. Connecting rods are generally made from robust materials such as steel, aluminum, or titanium alloys. The choice of material depends on factors like engine size, power output, and intended application. For instance, high-performance engines may require stronger materials