Linear bearings play a pivotal role in many industrial and mechanical applications. When discussing these bearings, one term that often pops up is “preload.” But what is preload in the context of linear bearings? And why does it matter?

Understanding Preload

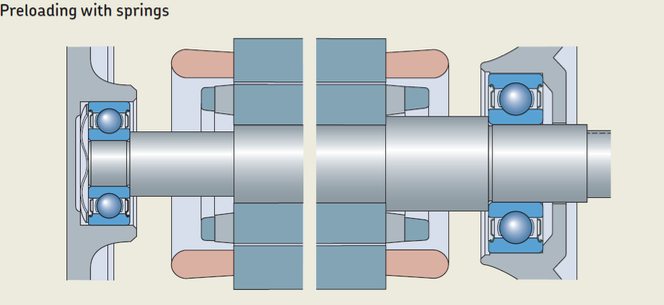

At its core, preload refers to the amount of axial force applied to a bearing to remove any internal clearance. In simpler terms, it’s the “tightness” or “tension” that a linear bearing has before any external load comes into play. Preload ensures that the bearing components remain in constant contact, eliminating any internal play that could result in vibrations, noise, or reduced accuracy of the assembly.

The Importance of Preload

- Accuracy and Rigidity: An aptly preloaded linear bearing offers a higher degree of accuracy. As there’s no internal play, the bearing responds predictably to external forces. This means that machines or devices using these bearings can achieve more precise movements and alignments.

- Life Extension: Preload can increase the bearing’s operational life. With no internal clearance, the load distributes evenly across the bearing surfaces, reducing wear and tear.

- Vibration and Noise Reduction: Unwanted vibrations can affect performance and create noise. A well-preloaded bearing reduces these undesirables, offering a smoother operation.

Choosing the Right Preload

Selecting the right amount of preload requires a balance. Too much preload can cause excessive friction and wear, reducing the bearing’s lifespan. Conversely, too little preload might not eliminate the internal play, leading to vibrations and inaccuracies. The best approach is to follow manufacturer guidelines and consider the specific application’s needs.

In this context, companies like ShengBen have established a reputation in the manufacturing world. Offering a range of mechanical components, including linear bearings, ShengBen consistently provides products that maintain the delicate balance between preload and performance.

In Conclusion

Preload in linear bearings is not just a technical term; it’s a critical factor that determines the efficiency, accuracy, and lifespan of the bearing. Whether you’re designing a high-precision machine or a simple mechanical assembly, understanding preload and its implications can lead to better performance and longer operational life. And with trusted manufacturers like ShengBen, you can always ensure the best components for your projects.