crankshaft is a key component of an internal combustion engine.

Its primary role is to convert the linear motion of the pistons into rotational motion.

This rotational movement then powers the vehicle’s wheels.

The performance and condition of the crankshaft significantly affect the engine’s efficiency, power, and smooth operation.

Introduction

Brief Explanation of the Crankshaft

The crankshaft is a key component of the internal combustion engine, designed to convert the reciprocating linear motion of the pistons into rotational motion. The crankshaft consists of a series of cranks and crankpins, which are attached to the pistons via connecting rods. It Irotates within the engine block through use of main bearings, providing the fundamental driving force for most cars, motorcycles, and heavy-duty vehicles. More details can be found on the Crankshaft Wikipedia page.

Importance of the Crankshaft in an Engine

As a pivotal element in the engine, the crankshaft plays an indispensable role in vehicle operation. It enables the engine to create a rotational movement, which subsequently drives the wheels of the vehicle. The crankshaft not only converts the piston’s linear movements into a rotation but also drives the engine’s various accessories, such as the oil pump, air conditioning compressor, mechanical water pump, alternator, and power steering pump. In essence, without a functioning crankshaft, an internal combustion engine cannot perform its intended function. More comprehensive information about the importance of the crankshaft in an engine can be found on the Internal Combustion Engine Wikipedia page.

History of the Crankshaft

Early Usage

The concept of the crankshaft has a long history, dating back to the Han Dynasty in China during the 2nd century BC. It was initially used in rudimentary applications, such as lifting heavy weights and water drawing. In the context of engines, however, the first recorded use of a crankshaft in a rotating engine was by an engineer of the Hellenistic age, Hiero of Alexandria, in one of his steam-powered devices. For further historical information, you can check the History of the Crankshaft on Wikipedia.

Development Over the Years

As technology evolved, so did the design and usage of crankshafts. In the 15th century, the crankshaft found its way into windmills and sawmills thanks to ingenious design tweaks. However, it was not until the advent of the internal combustion engine in the 19th century that the modern version of the crankshaft began to take shape. Initially, crankshafts were hand-cranked, but the advent of electric starters made them much more user-friendly. Over time, improvements in materials, manufacturing processes, and design made crankshafts more efficient and reliable. Details on the development of crankshafts over the years can be found on the Crankshaft Wikipedia page.

Modern Crankshafts

Modern crankshafts are intricate pieces of machinery designed to withstand high stress and last for hundreds of thousands of miles of engine operation. They are made from high-strength materials, such as forged steel, to resist the enormous forces exerted by the engine’s pistons. Some high-performance engines even use titanium crankshafts to further reduce weight and increase strength. Computer-aided design (CAD) and manufacturing (CAM) technologies have also led to the production of crankshafts with unprecedented precision and performance characteristics. The Crankshaft Wikipedia page provides a more in-depth look at modern crankshafts.

Design and Construction of Crankshafts

Materials Used

A variety of materials can be used in the production of crankshafts, but the primary requirement is that the material must be durable and able to withstand enormous pressure. The most common material used is cast iron due to its excellent strength and wear resistance. However, for high-performance or heavy-duty applications, forged steel is often chosen because of its superior strength and fatigue resistance. Other materials such as alloy steel, titanium, and even carbon fiber are used in high-performance racing and aeronautical applications. For more information on crankshaft materials, you may visit the Crankshaft Wikipedia page.

Manufacturing Process

The manufacturing process of a crankshaft is complex and involves a series of steps. Initially, a basic shape of the crankshaft is created either through casting or forging. Then, the material undergoes heat treatment to increase its hardness and strength. This is followed by machining, where the crankshaft is precisely shaped and balanced. Additional processes like surface hardening or nitriding might be employed to enhance the durability of the crankshaft. Finally, the crankshaft is inspected and tested for quality assurance. You can learn more about this on the Crankshaft manufacturing Wikipedia page.

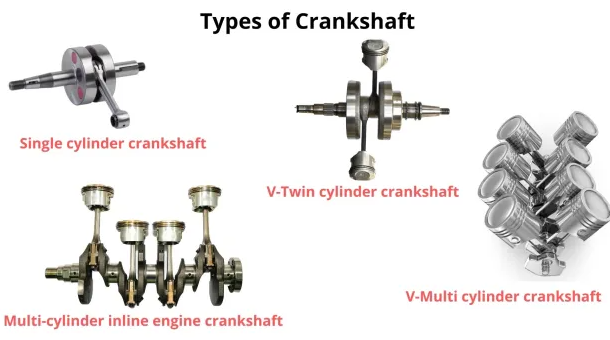

Types of Crankshafts

There are several types of crankshafts, each designed for specific types of engines or applications. The most common ones are the ‘monolithic’ or ‘one-piece’ crankshafts, which are typically found in most passenger vehicles. However, there are also ‘assembled’ or ‘built-up’ crankshafts, usually found in large industrial engines. Furthermore, ‘flat plane’ and ‘cross plane’ crankshafts are distinct types used specifically in V8 engines, with each type contributing to different engine characteristics. More detailed information can be found on the Crankshaft design Wikipedia page.

Role of the Crankshaft in Engine Operation

Conversion of Linear Motion to Rotational Motion

The primary function of the crankshaft is to convert the linear motion of the pistons into rotational motion. As the pistons move up and down in the engine’s cylinders due to the combustion process, this motion is transferred to the crankshaft via connecting rods attached to crankpins. As the connecting rods push and pull, the crankshaft rotates, thus transforming the piston’s reciprocating motion into rotation, which eventually powers the vehicle’s wheels. More information on this can be found on the Crankshaft Wikipedia page.

Function in the Four-Stroke Engine Cycle

The crankshaft plays a pivotal role in the four-stroke engine cycle, which includes intake, compression, combustion (or power), and exhaust strokes. The rotation of the crankshaft allows the intake and exhaust valves to open and close at the correct times during each cycle. Moreover, the crankshaft ensures that the pistons are in the right position during the compression and power strokes, thus allowing for optimal engine operation. The Four-Stroke Engine Wikipedia page provides a more detailed explanation of this process.

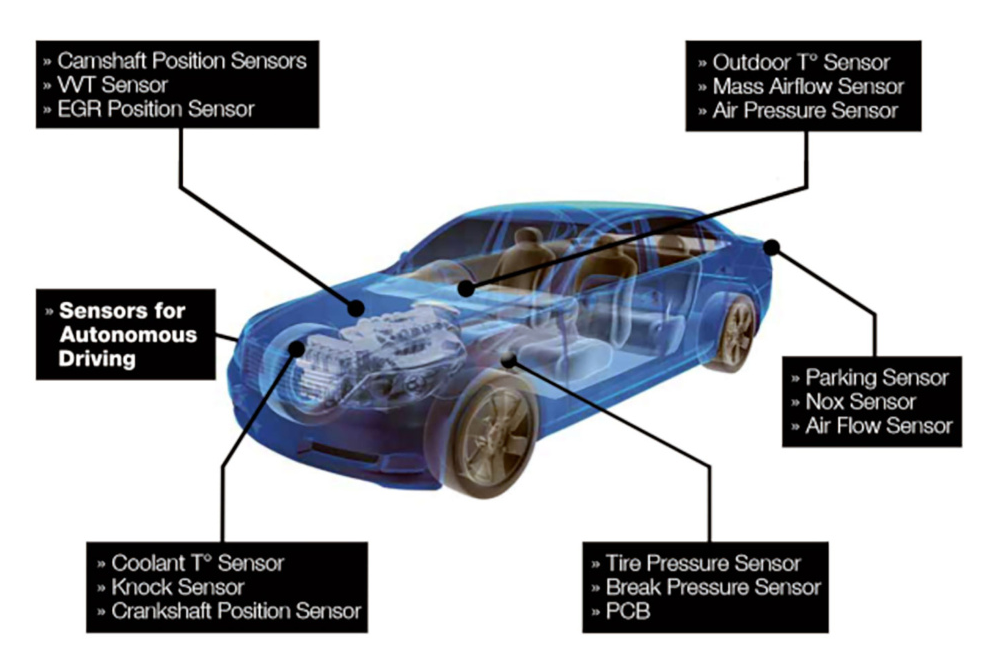

Interaction with Other Engine Components

The crankshaft does not operate in isolation; it interacts with various other engine components to ensure the smooth running of the engine. For instance, it works closely with the camshaft to control the timing of the valves. The timing belt or chain synchronizes the rotation of the crankshaft and the camshaft. Additionally, the crankshaft drives the engine’s oil pump and alternator, which supply oil for lubrication and generate electricity for the vehicle, respectively. A comprehensive understanding of these interactions can be gained from the Internal Combustion Engine Wikipedia page.

How to Identify Crankshaft Problems

Common Signs of a Failing Crankshaft

Several symptoms can indicate a failing crankshaft. These may include: engine vibration, loss of power, poor fuel economy, engine misfires, or an engine that does not start at all. In some cases, an oil leak may be seen under the vehicle, which can be a sign of a damaged crankshaft seal. Additionally, noises such as a knocking, rattling, or slapping sound from the engine might be a sign of crankshaft problems. Further details can be found on the Crankshaft Wikipedia page.

Diagnostic Techniques

Diagnosing crankshaft problems often requires professional expertise and tools. Computerized diagnostic equipment is typically used to detect any abnormalities or error codes that may point to a crankshaft issue. In some instances, a mechanic may perform a physical inspection of the crankshaft using specific tools, such as a crankshaft deflection gauge, to measure any deviations in the crankshaft’s rotation. For a comprehensive understanding, please visit the Engine Diagnosis Wikipedia page.

Possible Effects on Vehicle Performance

The consequences of a failing crankshaft can be serious and may severely impact vehicle performance. The vehicle may suffer from a significant reduction in power, efficiency, and smoothness of operation. It may also result in higher emissions, which can lead to a failed emissions test. In extreme cases, a damaged crankshaft could cause the engine to seize or fail altogether, making the vehicle undrivable. More insights can be found on the Internal Combustion Engine Wikipedia page.

Maintaining and Replacing

Preventive Measures

Preventive maintenance is key to extending the life of your crankshaft and avoiding potential problems. Regular engine oil changes are critical as they ensure that the crankshaft is adequately lubricated. Using high-quality engine oil and filters can also help prevent contaminants from damaging the crankshaft and other engine components. Regular engine inspections, either by yourself or a professional, can help identify potential issues before they become serious problems. Additional details can be found on the Vehicle Maintenance Wikipedia page.

Procedures for Replacement

Replacing a crankshaft is a complex procedure typically performed by professional mechanics. The engine needs to be removed from the vehicle, and several parts, such as the oil pan, pistons, and connecting rods, must be disassembled to access the crankshaft. Once the old crankshaft is removed, the new one must be installed and properly aligned, and all the other parts must be reassembled. The engine is then reinstalled in the vehicle, and a series of tests are performed to ensure everything is functioning correctly. You can read more about this on the Engine Rebuilding Wikipedia page.

Costs and Considerations

The cost of replacing a crankshaft can vary greatly depending on the make and model of the vehicle, the type of crankshaft, and labor costs. It can be an expensive repair due to the complexity of the process and the time it takes to complete it. However, ignoring a faulty crankshaft can lead to more severe and costlier damage. Therefore, it is recommended to consult with a professional mechanic if you suspect your crankshaft might be faulty. For more insights, please refer to the Auto Repair Wikipedia page.

The Future of Crankshafts

Technological Advancements

As technology continues to advance, so does the design and manufacturing of crankshafts. Computer-aided design (CAD) and computer-aided manufacturing (CAM) are now the industry standard, allowing for highly precise and efficient production. Additionally, advances in materials science are leading to the development of stronger, lighter crankshafts. For instance, FEDA, a prominent player in the automotive industry, has been investing in research and development to improve the strength-to-weight ratio of their crankshafts, with promising results. For further information about technological advancements in the industry, you may visit the Automotive Engineering Wikipedia page.

Impact of Electric Vehicles on Crankshaft Design and Usage

The rise of electric vehicles (EVs) has had a significant impact on the future of crankshafts. As EVs do not use internal combustion engines, they do not require crankshafts. This shift in the automotive industry has led manufacturers, including FEDA, to reconsider their strategies and invest in the development of electric drivetrain components. However, as long as internal combustion engines are in use, the demand for crankshafts will continue. Understanding the impact of EVs on the automotive industry will be crucial for companies to navigate the future landscape. More details can be found on the Electric Vehicle Wikipedia page.

Conclusion

Recap of Crankshaft’s Role and Importance

The crankshaft is a fundamental component of the internal combustion engine, playing a vital role in converting the linear motion of the pistons into rotational motion. Its performance significantly impacts the overall efficiency, power, and smoothness of the engine operation. From its historical development to its design and manufacturing processes, the complexity and significance of the crankshaft should not be underestimated. You can find more information on the Crankshaft Wikipedia page.

Final Thoughts on Crankshaft Maintenance and Future

Proper maintenance of the crankshaft is crucial in ensuring the longevity of your engine. Regular inspections, using quality engine oil, and timely replacements can prevent severe engine damage and maintain optimal performance. The future of the crankshaft lies in the balance between technological advancements in materials and design and the transition to electric vehicles. Brands like FEDA are making strides in this direction, reflecting the evolving nature of the automotive industry. For an overview of the impact of these changes, you might want to visit the Automotive Industry Wikipedia page. As we navigate this transitional period in automotive history, the understanding and appreciation of components like the crankshaft remain vital.

References

- Crankshaft – Wikipedia

- Four-stroke engine – Wikipedia

- Internal combustion engine – Wikipedia

- Engine diagnosis – Wikipedia

- Vehicle maintenance – Wikipedia

- Engine rebuilding – Wikipedia

- Auto repair – Wikipedia

- Automotive engineering – Wikipedia

- Electric vehicle – Wikipedia

- Automotive industry – Wikipedia