Connecting rod manufacturers hold a vital position within the automotive and engine parts manufacturing industry.

This sector is dynamic and continually evolving in response to trends and technological advancements in the broader automotive industry.

Introduction

Overview of the Connecting Rod Industry

Connecting rods are integral components in many mechanical systems, especially in automotive engines. They serve as critical links between the piston and the crankshaft, transforming the piston’s linear motion into the crankshaft’s rotary motion. This process is fundamental for the operation of any internal combustion engine.

The connecting rod industry has significantly evolved over the years, adopting new materials and manufacturing technologies to increase the durability and performance of connecting rods. Manufacturers have been focusing on reducing the weight of the rods, improving strength, and minimizing friction to enhance overall engine efficiency.

Importance of Connecting Rods in Various Applications

Connecting rods are essential not only in the automotive industry but also in various applications across different industries.

In the automotive industry, the quality of connecting rods significantly affects the vehicle’s performance and fuel efficiency. Manufacturers continually strive to produce lighter, stronger, and more durable connecting rods to meet the evolving demands of this industry.

In aircraft and marine applications, the connecting rods’ reliability is of utmost importance. The use of high-quality connecting rods ensures the efficient operation of engines, thereby playing a critical role in overall vehicle performance and safety.

They contribute to the operational efficiency of these machines, directly influencing their performance and durability.

As such, the importance of connecting rods extends far beyond their function. They play a critical role in a wide range of applications, reinforcing their significance in various industries.

Here are a few noteworthy ones:

- FEDA: China leading manufacturer and exporter specializing in auto engine parts, with a particular focus on connecting rods and crankshafts. Their products are suitable for a variety of automobile engines.

- Thyssenkrupp: Thyssenkrupp is a multinational conglomerate with a strong presence in the automotive industry. They are known for their high-performance connecting rods.

- Crower: Crower is a well-established name in the high-performance automotive aftermarket industry, producing high-quality connecting rods, among other components.

- Wiseco: Wiseco is a world leader in manufacturing pistons, crankshafts, and connecting rods for motorcycles, ATVs, snowmobiles, outboard marine engines, and automobiles.

- Pauter Machine: Pauter Machine is a specialty manufacturer known for its high-strength, high-quality connecting rods, designed to handle the most demanding engine applications.

- MAHLE: MAHLE is a leading global supplier to the automotive and engine industry. Their product portfolio includes a wide range of connecting rods suitable for different applications.

Detailed Overview of Connecting Rod Products

Types of Connecting Rods

Connecting rods come in a variety of types, primarily differentiated by the materials used in their construction and their intended applications.

- I-beam Connecting Rods: As the name implies, these rods have a shape that resembles the letter ‘I’ when viewed in cross-section. I-beam rods are typically used in high-torque engines, as they have a good balance of weight and strength.

- H-beam Connecting Rods: H-beam rods are shaped like the letter ‘H’ in cross-section and are generally stronger but heavier than I-beam rods. These are commonly used in high-performance engines where high RPM and horsepower are required.

- A-beam Connecting Rods: A-beam rods are a balance between I-beam and H-beam rods. They offer a good blend of weight and strength, making them suitable for a range of applications.

More about Connecting Rods on Wikipedia.

Material Choices and Their Impact on Performance

Different materials used in the construction of connecting rods impact their performance and application.

- Steel: Traditionally, connecting rods have been made from various types of steel. Steel rods are robust and reliable, suitable for a broad range of applications.

- Aluminum: Aluminum connecting rods are much lighter than steel, which can lead to increased engine efficiency. However, they may not be as strong or durable as their steel counterparts.

- Titanium: Titanium rods combine the benefits of steel and aluminum. They are lightweight like aluminum and strong like steel, but they are generally more expensive.

The choice of material is often a balance between performance, durability, and cost.

Specific Product Offerings from Each Manufacturer

FEDA’s Product Offerings

FEDA offers a wide range of connecting rods and crankshafts. They cater to various automobile engines including those from brands like Benz, Volvo, BMW, Porsche, VW, Audi, Peugeot, Ford, Chevrolet, Toyota, Nissan, Mitsubishi, Hyundai, and more.

Customization Options and Services

Some manufacturers, including FEDA, offer customization services, allowing customers to have connecting rods and crankshafts tailored to their specific needs. These services often involve adjusting the dimensions, material choice, or design features of the rods to match unique engine specifications or performance goals.

Customization can enhance the compatibility and performance of the connecting rods, catering to specialized applications or distinct performance requirements. Consult with the manufacturer or visit their websites for more details on their customization services.

Advanced Technologies and Innovations in Connecting Rod Manufacturing

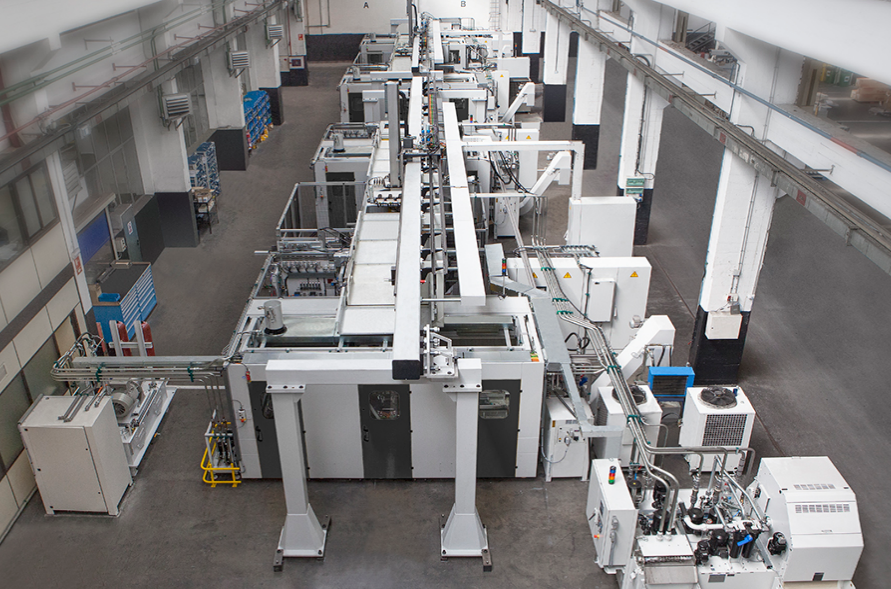

Current Technologies Used in Manufacturing

The manufacturing of connecting rods has significantly advanced over the years, employing modern technologies for improved precision and quality. Current technologies include:

- CNC Machining: CNC machining allows for high-precision manufacturing, creating connecting rods that adhere to exact specifications with minimal variance. This ensures optimal fit and performance in engines.

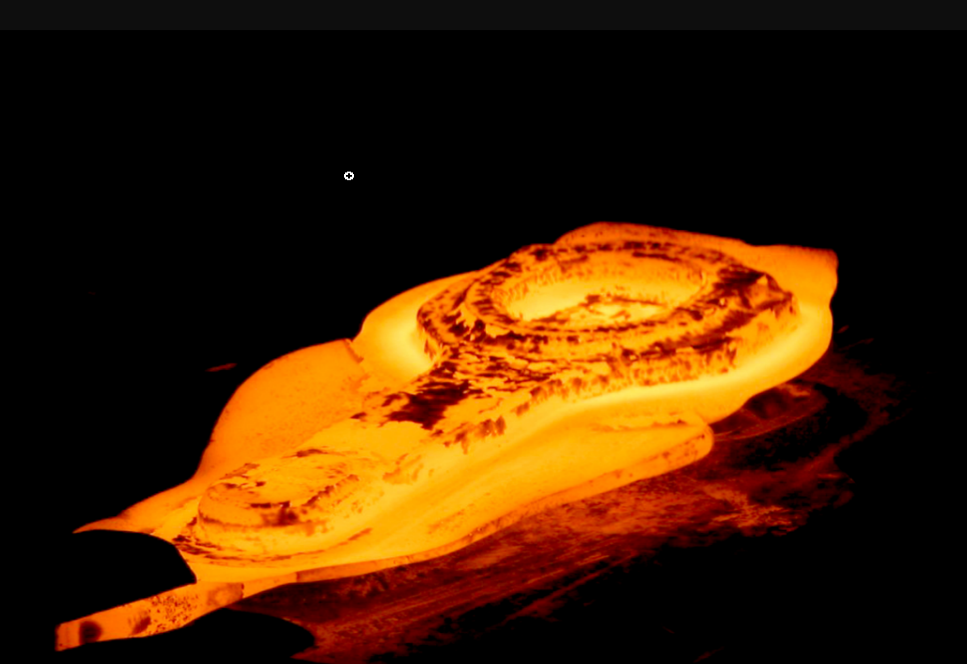

- Heat Treatment: Techniques such as case hardening and tempering are used to improve the strength and durability of the connecting rods. This enhances their resistance to the significant stresses they endure during engine operation.

- Friction Stir Welding: This innovative welding process is used to join aluminum connecting rods. It provides superior joint strength and integrity compared to traditional welding methods.

Recent Innovations and their Impact on Product Quality

Advancements in materials science and manufacturing technologies have significantly improved the quality of connecting rods. New alloys and composite materials enhance strength and reduce weight, while innovative manufacturing techniques like additive manufacturing (3D printing) allow for the creation of more complex, performance-optimized designs.

Role of Emerging Technologies (AI, IoT, etc.)

Emerging technologies like Artificial Intelligence (AI) and the Internet of Things (IoT) have started to influence the connecting rod manufacturing industry.

Predictive maintenance, powered by AI and IoT, can help identify potential equipment issues before they cause downtime, enhancing overall production efficiency and reducing costs.

Manufacturers’ R&D Capabilities and Future Directions

Leading connecting rod manufacturers like FEDA invest heavily in research and development to continually improve their products and stay ahead of industry trends. They explore new materials, designs, and manufacturing techniques to optimize the performance, durability, and cost-effectiveness of their connecting rods.

FEDA’s commitment to innovation is evident in their comprehensive product range and their ability to cater to specific customer requirements. The company aims to leverage advanced technologies and industry knowledge to drive future developments, paving the way for the next generation of high-performance connecting rods.

Quality Assurance in Connecting Rod Production

Standards and Certifications

Quality assurance starts with adhering to recognized industry standards and obtaining relevant certifications. Manufacturers like FEDA typically comply with international standards such as ISO 9001, which sets out criteria for quality management systems.

Quality Control Processes in Manufacturing

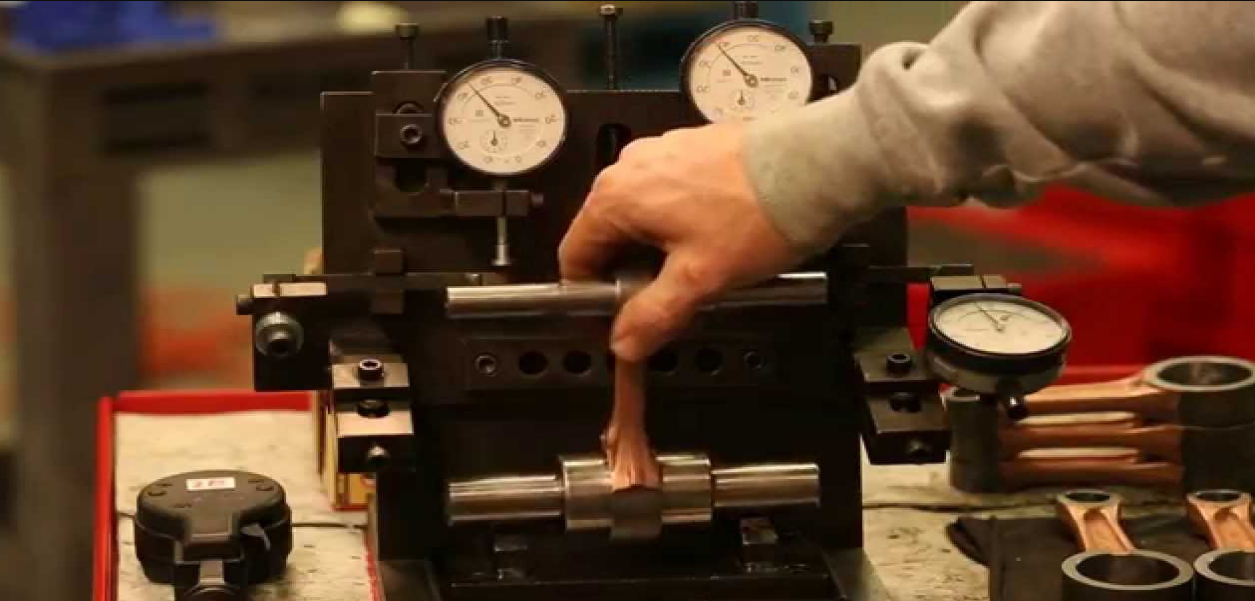

Quality control is integral to the manufacturing process of connecting rods. It involves rigorous inspections and checks at each stage of production, from raw material selection to final assembly.

Manufacturers employ various methods to ensure quality, such as:

- Dimensional Checks: Connecting rods are measured for precise dimensions using advanced measurement tools to ensure they match the design specifications.

- Material Inspection: Raw materials are thoroughly inspected and tested to confirm their quality and suitability for the application.

- In-Process Inspection: During manufacturing, connecting rods undergo several in-process inspections to identify and correct any issues early on, thus preventing defective parts from reaching the final stages of production.

Post-Production Testing and Verification

These may include:

- Tensile Testing: This tests the rod’s strength and ability to withstand high forces without breaking.

- Fatigue Testing: In fatigue testing, rods are subjected to repeated cycles of stress to simulate the conditions they would experience in an engine. This helps manufacturers ensure the rods can withstand long-term use.

- Dimensional Verification: Final dimensional checks are carried out to ensure the rods meet the design specifications.

Manufacturers may also conduct additional tests based on the specific application of the connecting rod or as per the requirements of their clients. Ensuring high-quality products is a top priority in the industry, reflecting on the manufacturer’s reputation and customer satisfaction.

Market Positioning and Strategies of Connecting Rod Manufacturers

Market Analysis and Trends

As demand for more fuel-efficient and high-performance engines grows, manufacturers are increasingly focusing on producing lightweight yet strong connecting rods. Advances in materials science and manufacturing technology are driving these developments.

Furthermore, the growth of the electric vehicle market might alter demand dynamics for connecting rods, leading manufacturers to explore new product offerings or markets.

Manufacturers’ Target Markets and Strategies

Manufacturers strategically target markets based on several factors, including geographical location, type of industry (e.g., automotive, aerospace, marine), and specific customer requirements.

For instance, FEDA targets a broad range of markets with its versatile product line. Their products cater to a variety of vehicle brands, showing their strategy to serve a diverse automotive market.

Competitive Advantages and Differentiators of Each Manufacturer

Each manufacturer in the connecting rod industry has unique strengths that set them apart.

For FEDA, their competitive advantages include their comprehensive product offerings, ability to provide customized solutions, and their longstanding industry experience. The company’s commitment to quality, demonstrated by rigorous quality control and adherence to international standards, further enhances their reputation in the market.

Future Prospects and Predictions

Looking ahead, the connecting rod industry is likely to continue innovating in response to evolving market demands. The rise of electric vehicles and renewable energy may open new opportunities for manufacturers.

For a versatile and adaptive company like FEDA, the future holds promise. The company is likely to continue to invest in R&D to stay at the forefront of technology and maintain its competitive edge.

References

The connecting rod industry is a critical segment of the broader automotive and engine parts manufacturing sector. Here are some resources that offer further reading about the topic:

- Connecting Rod – Wikipedia: This Wikipedia entry provides a comprehensive overview of connecting rods, including their function, design, materials, and manufacturing processes.

- Automotive Industry – Wikipedia: This article gives an overview of the automotive industry, where many connecting rod manufacturers operate.

- List of Auto Parts – Wikipedia: This is a comprehensive list of auto parts, including engine components like connecting rods.

- Engine Components – Wikipedia: This section of the engine’s Wikipedia page discusses various engine components and their functions, including the connecting rod.

- Materials Science – Wikipedia: This entry explains the science behind the materials used in manufacturing processes, such as the metals commonly used in connecting rods.