Replacing a connecting rod in your engine might seem like a complex task. However, with the right knowledge and skill set, you can perform this task efficiently to upgrade your vehicle’s performance. This article aims to provide insights into the process of replacing a connecting rod, explaining its role, necessary tools, the replacement procedure, and crucial safety measures.

Understanding the Importance of the Connecting Rod in Your Engine

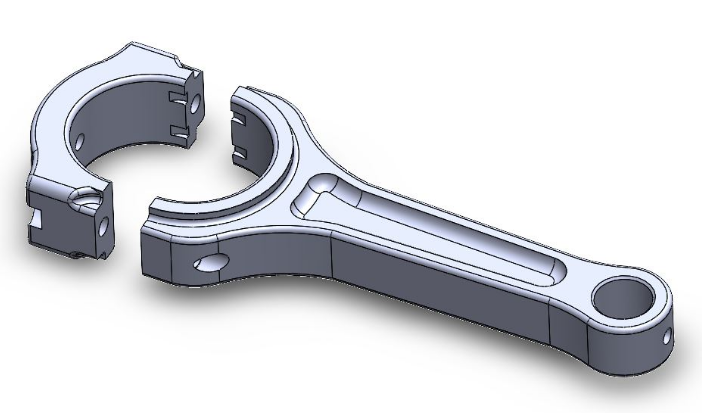

As a critical link in your vehicle’s internal combustion engine, the connecting rod is responsible for transforming the linear motion of the piston into rotary motion for the crankshaft. This transfer of power is crucial for driving the vehicle. A faulty connecting rod can significantly hamper your engine’s performance, making its timely replacement essential.

Recognizing the Need for a Connecting Rod Replacement

Some signs indicating a need for connecting rod replacement include a knocking sound coming from the engine, loss of power, reduced fuel efficiency, or worst-case scenario, complete engine failure. Acting swiftly on these issues can prevent further damage and avoid potential costly repairs.

Essential Tools for Replacing a Connecting Rod

You’ll need a specific set of tools to replace a connecting rod. These usually consist of a torque wrench for tightening bolts, a rod extractor for removing the old rod, and pliers for securing the piston rings during reassembly. Some situations may also require a piston ring compressor and a honing tool for cleaning the cylinder bore.

Procedure of Replacing a Connecting Rod

The process of replacing a connecting rod involves removing the engine, disassembling the piston-cylinder system, extracting the old connecting rod, installing the new one, and reassembling all parts. Each step should be carried out meticulously and according to manufacturer guidelines. Consulting a repair manual specific to your vehicle model is recommended.

Safety Measures during Connecting Rod Replacement

During the replacement process, it’s crucial to avoid inflicting damage to the connecting rod or associated components. Precision is key to maintain the balance and alignment of the internal engine components. Also, make sure the rod is adequately lubricated during reassembly to prevent premature wear.

Revitalizing Engine Performance with Connecting Rod Replacement

Knowing how to replace a connecting rod is a valuable skill not just for mechanics, but also for vehicle owners and car enthusiasts wishing to prolong the life of their engines. Prompt and proper replacements can increase engine performance, fuel efficiency, and vehicle reliability, making it a significant endeavor for any car owner.