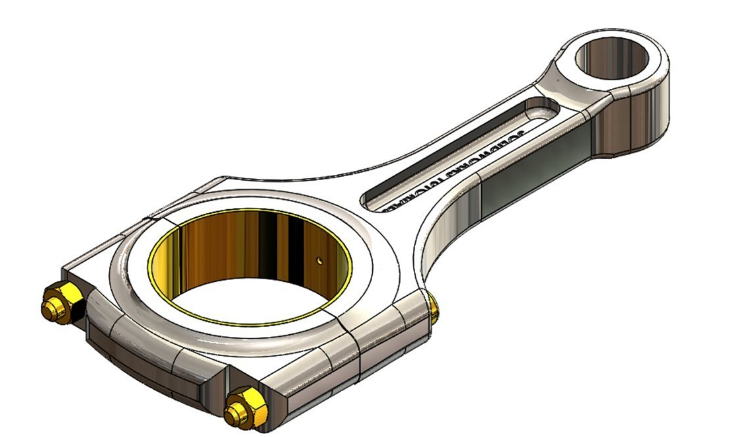

The ability to accurately measure connecting rod bearing clearance is integral to maintaining and enhancing the performance of your engine. Connecting rod bearing clearance is the small gap between the engine’s crankshaft and the connecting rod’s bearing that enables the crankshaft to move freely and efficiently. This comprehensive guide will explore the tools required, the steps to accurately measure this clearance, and the importance of this measurement in preserving engine efficiency.

Understanding Connecting Rod Bearing Clearance

The connecting rod bearing clearance plays a vital role in the functioning of an engine. It allows a thin film of oil to be formed, ensuring the crankshaft and the bearing do not have metal-to-metal contact, thereby reducing friction and wear.

The Tools Required

Accurately measuring connecting rod bearing clearance involves precision tools, such as a micrometer, feeler gauge, or a dial bore gauge. These tools can accurately gauge the minuscule gap between the crankshaft and the bearing surface.

Key Steps to Measure Connecting Rod Bearing Clearance

Measurement of Crankshaft Journal Diameter

The diameter of the crankshaft journal, the surface where the bearing mounts, needs to be accurately measured using a micrometer. Consistent measurements around the circumference ensure the roundness of the journal.

Measurement of Connecting Rod Bearing Diameter

After installing the bearing in the rod, the internal diameter of the bearing is measured using a dial bore gauge. This measurement must be taken at several points to confirm the bearing’s roundness.

Calculating the Clearance

The clearance is obtained by subtracting the crankshaft journal diameter from the connecting rod bearing diameter.

Significance of Accurate Measurements

Inadequate or excessive bearing clearance can result in catastrophic engine failure. A tight clearance may cause insufficient lubrication, leading to increased friction and potential seizure. In contrast, excessive clearance may lead to poor oil control, resulting in lower oil pressure and subsequent damage to other engine components.

Effect of Correct Bearing Clearance on Engine Performance

Achieving the correct bearing clearance enhances engine performance. It ensures efficient oil flow, optimal heat transfer, and minimal friction. These factors culminate in increased engine efficiency, power, and longevity.

Conclusion: The Precision in Detail

Mastering how to measure connecting rod bearing clearance is a critical skill set for those in engine assembly, maintenance, or any automotive enthusiast seeking optimal engine performance. It ensures efficient lubrication, reduces engine wear, and promotes overall engine health. As such, paying meticulous attention to this seemingly minor detail significantly contributes to the broader spectrum of engine performance and sustainability.