A crankshaft is a fundamental component of an internal combustion engine, tasked with converting the linear motion of the pistons into rotational motion to power the vehicle. The design, material, and construction of crankshafts can vary significantly depending on the intended use, the type of vehicle, and the engine’s specific requirements. There are three primary types of crankshafts: cast crankshafts, forged crankshafts, and billet crankshafts.

Cast crankshafts are the most common type found in production vehicles. This type of crankshaft is made by pouring molten metal into a mold in the shape of the crankshaft, which is then allowed to cool and solidify. Cast iron and cast steel are typically used in this process. The advantage of this method is that it is relatively inexpensive and efficient for mass production. However, cast crankshafts are not as strong as other types and may not be suitable for high-performance applications.

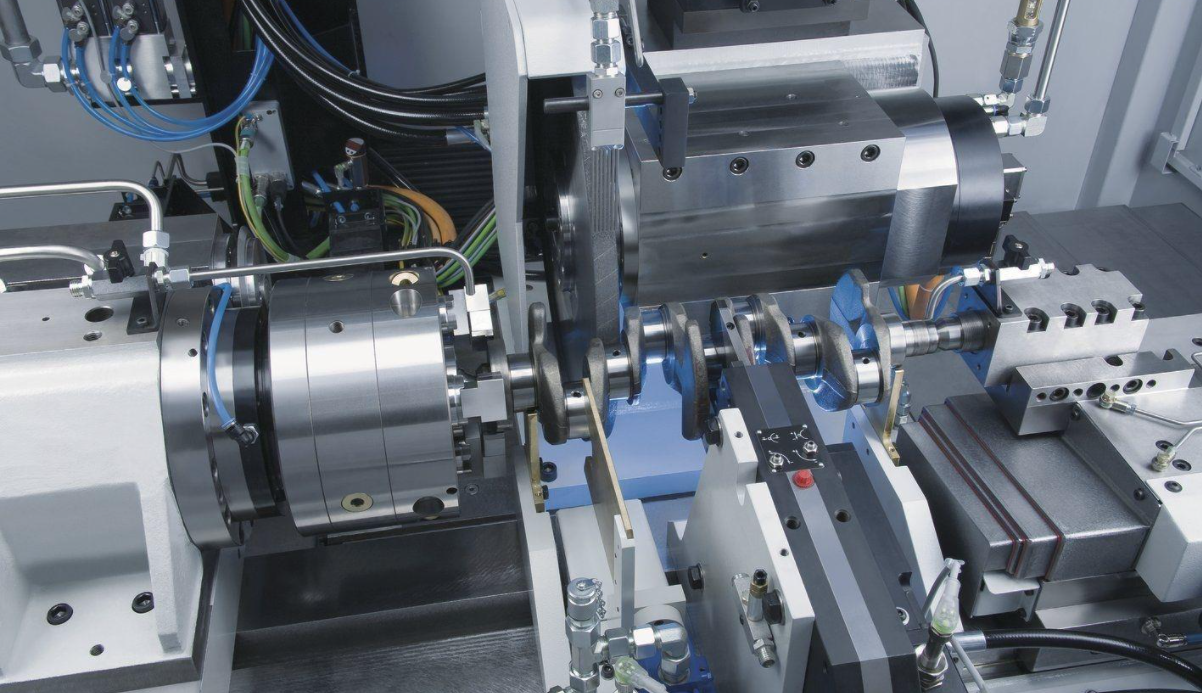

Forged crankshafts are stronger and more durable than cast crankshafts. These crankshafts are made by heating a piece of metal to high temperatures and then using a high-pressure hammer or press to shape it into the desired form. The forging process aligns the grain structure of the metal, making the crankshaft stronger and more resistant to wear and tear. Forged crankshafts are typically found in high-performance or heavy-duty vehicles where the engine is subject to high stresses.

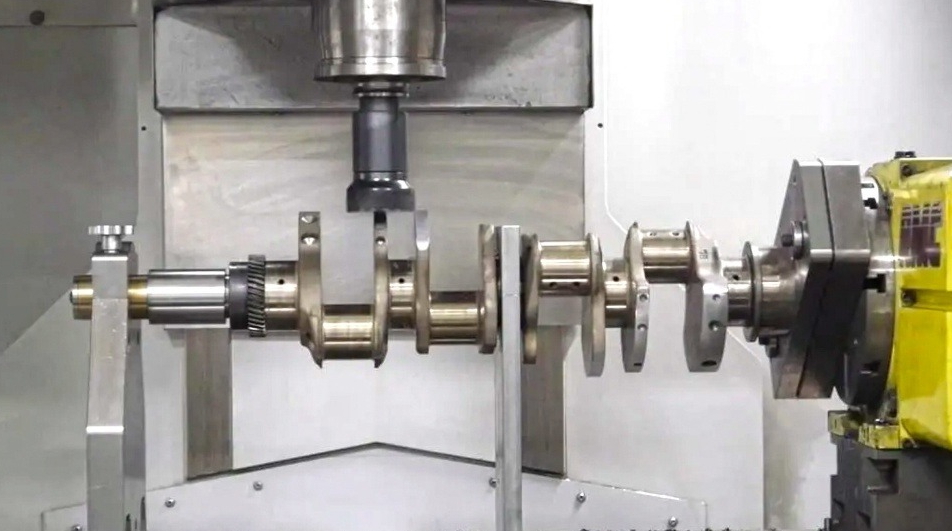

The third type is the billet crankshaft. Billet crankshafts are machined from a solid piece of metal, typically a high-quality steel alloy. This method of production allows for the most precise control over the design and dimensions of the crankshaft. Billet crankshafts are the strongest type, and they offer the best performance. However, the process of creating a billet crankshaft is time-consuming and expensive, making these crankshafts less common and primarily found in specialized or high-performance applications.

Each type of crankshaft has its advantages and disadvantages, and the best choice depends on the specific requirements of the engine. While cast crankshafts may be perfectly suitable for most everyday vehicles, performance or heavy-duty vehicles may benefit from the added strength and durability of a forged or billet crankshaft.

Understanding the different types of crankshafts is essential for anyone interested in engine mechanics or car performance. By knowing the strengths and weaknesses of each type, you can make more informed decisions about engine repair or modification. Remember, the crankshaft plays a crucial role in the performance and longevity of your vehicle’s engine, so it’s worth taking the time to understand the different types and what they offer.

1. Introduction to Crankshafts

A crankshaft is a fundamental component of an internal combustion engine. It converts the linear motion of the pistons into rotational motion to power the vehicle. The design, material, and manufacturing process of crankshafts can significantly vary, with each type offering unique advantages and limitations.

2. Cast Crankshafts

Cast crankshafts are the most common type found in production vehicles. They are made by pouring molten metal into a mold in the shape of the crankshaft, which is then allowed to cool and solidify. The primary advantage of this method is its cost-effectiveness and efficiency, making it suitable for mass production. However, cast crankshafts are not as robust as other types and may not be ideal for high-performance applications.

3. Forged Crankshafts

Forged crankshafts are known for their strength and durability. They are made by heating a piece of metal to high temperatures and shaping it into the desired form using a high-pressure hammer or press. The forging process aligns the metal’s grain structure, enhancing the crankshaft’s strength and wear resistance. Forged crankshafts are typically used in high-performance or heavy-duty vehicles subjected to high stresses.

4. Billet Crankshafts

Billet crankshafts are machined from a solid piece of metal, typically a high-quality steel alloy. This method offers the most precise control over the design and dimensions of the crankshaft. Billet crankshafts are the strongest type and offer the best performance. However, the process of creating a billet crankshaft is time-consuming and expensive, making these crankshafts less common and primarily used in specialized or high-performance applications.

5. Choosing the Right Crankshaft

The optimal crankshaft type depends on the specific requirements of the engine. While cast crankshafts are suitable for most everyday vehicles, performance or heavy-duty vehicles may benefit from the enhanced strength and durability of a forged or billet crankshaft. It’s crucial to consider your vehicle’s needs and intended use when choosing a crankshaft.

6. Conclusion

Understanding the different types of crankshafts is essential for anyone interested in engine mechanics or vehicle performance. Each type has its unique strengths and weaknesses, and knowing these can guide more informed decisions about engine repair or modification. The crankshaft plays a pivotal role in your vehicle’s engine performance and longevity, making it crucial to select the most suitable type.