A fundamental question often asked in the realm of automotive mechanics is, “How many crankshafts are in a V8?”. The answer is simple: there is only one crankshaft in a V8, or any other type of internal combustion engine, regardless of the number of cylinders. The crankshaft serves as the backbone of the engine, converting the linear motion of the pistons into rotational motion to drive the vehicle.

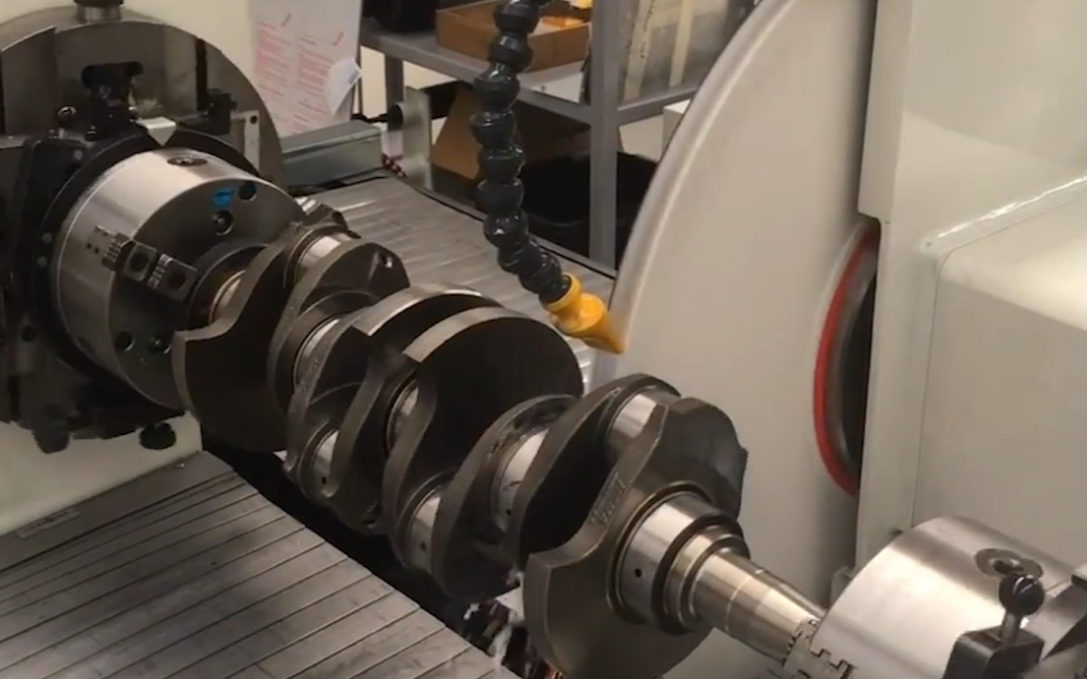

Understanding the manufacturing process of a crankshaft provides a deeper insight into its importance and functionality within an engine. This process involves a series of complex steps, each critical to the strength, balance, and durability of the crankshaft.

The initial stage in the manufacturing of a crankshaft is the creation of a raw casting or forging. This is typically done using high-quality steel or iron. The choice of material depends on the application, with steel often used for high-performance or heavy-duty engines due to its superior strength and durability.

The casting or forging is then machined to create the main journals and rod journals. The main journals are the parts of the crankshaft that sit in the engine block and support the crankshaft’s rotation. The rod journals, or crankpins, are offset from the main journals and attach to the connecting rods, which link the crankshaft to the pistons.

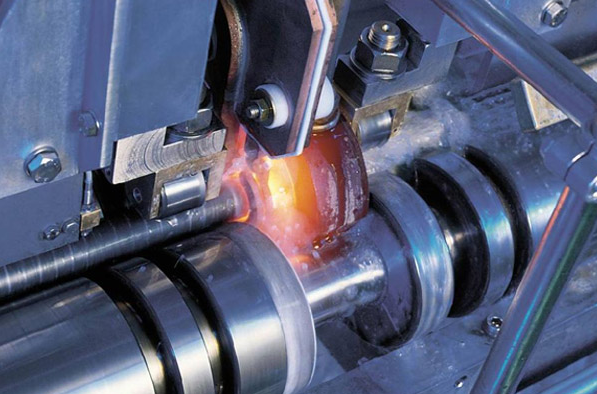

Once the machining process is complete, the crankshaft undergoes a heat treatment process to enhance its strength and durability. This is an essential step in ensuring the crankshaft can withstand the intense forces it will encounter during engine operation.

The next step is grinding. This process involves removing a small amount of material from the main and rod journals to create a smooth, polished surface. Grinding is critical because it reduces friction and wear during engine operation.

After grinding, the crankshaft is often balanced. This process involves adding or removing material to ensure that the crankshaft rotates smoothly without causing excessive vibration. Balancing is crucial for engine performance, longevity, and the comfort of the vehicle’s occupants.

The final stage in crankshaft manufacturing is inspection. Each crankshaft is meticulously inspected for defects, imbalances, or other issues that could affect its performance or durability. This quality control step ensures that every crankshaft meets the high standards required for use in an engine.

In essence, while there is only one crankshaft in a V8 engine, the process of creating this single, vital component is a complex and meticulous one. It requires careful consideration of materials, precise machining, and rigorous quality control to produce a component capable of withstanding the harsh environment inside an engine. This understanding underscores the importance of regular maintenance and proper care of the engine’s crankshaft.

Introduction: The question, “How many crankshafts are in a V8?” might seem straightforward for automotive enthusiasts. However, for those new to engine mechanics, the answer might not be as obvious. To clarify, there is only one crankshaft in a V8, as with any other internal combustion engine. This component is essential for transforming the linear motion of the pistons into rotational motion, ultimately driving the vehicle. This article will delve into the intricate process of manufacturing a crankshaft and the various stages involved.

Table of Contents & Content:

The Role of the Crankshaft in a V8

This section will delve into the fundamental function of a crankshaft in a V8 engine, highlighting its importance in the engine’s overall operation.

Materials Used in Crankshaft Manufacturing

A discussion of the materials, typically high-grade steel or iron, used in the production of crankshafts.

The Casting or Forging Process

An exploration of the initial steps of crankshaft manufacturing, where a raw casting or forging is created.

Machining of the Crankshaft

Here, we will delve into the process of machining the main journals and rod journals on the crankshaft.

Heat Treatment in Crankshaft Manufacturing

A discussion on the heat treatment process, a critical step that ensures the crankshaft can endure the immense forces it encounters during engine operation.

The Importance of Grinding

This part will explore the grinding process, which creates a smooth, polished surface on the journals to reduce friction and wear.

Balancing the Crankshaft

This section will discuss the balancing process, a step that ensures the crankshaft rotates smoothly, enhancing engine performance and longevity.

Final Inspection and Quality Control

An overview of the inspection process, where each crankshaft is meticulously examined for potential defects or imbalances.

Crankshaft Installation in a V8 Engine

This part will cover the installation process of the crankshaft in a V8 engine.

The Role of the Crankshaft in Engine Timing

A discussion of how the crankshaft is crucial for maintaining accurate engine timing.

The Relationship between the Crankshaft and Pistons

An exploration of how the crankshaft and pistons work together to drive the engine.

Understanding Crankshaft Failures

This section will discuss common causes of crankshaft failures and the signs to look for.Absolutely, let’s continue:

Maintenance and Care for the Crankshaft

This section will provide information on maintaining the crankshaft to extend its lifespan and ensure optimal engine performance.

The Impact of Crankshaft Design on Engine Performance

Here, we will delve into how the design and specifications of a crankshaft affect the performance of the engine.

Crankshaft Replacement: When and Why?

This part will discuss the conditions under which a crankshaft might need to be replaced, and the reasons behind it.

Importance of Precision in Crankshaft Manufacturing

An examination of why precision is so critical in the manufacturing process of the crankshaft, particularly in relation to engine performance and efficiency.

The Evolution of Crankshaft Manufacturing

This section will track the evolution of crankshaft manufacturing, highlighting advancements in materials and technologies over the years.

Conclusion: Understanding the Crankshaft in a V8

We wrap up by summarizing the importance of understanding the role and manufacturing process of the crankshaft in a V8 engine, and how this knowledge can lead to better vehicle maintenance and performance.