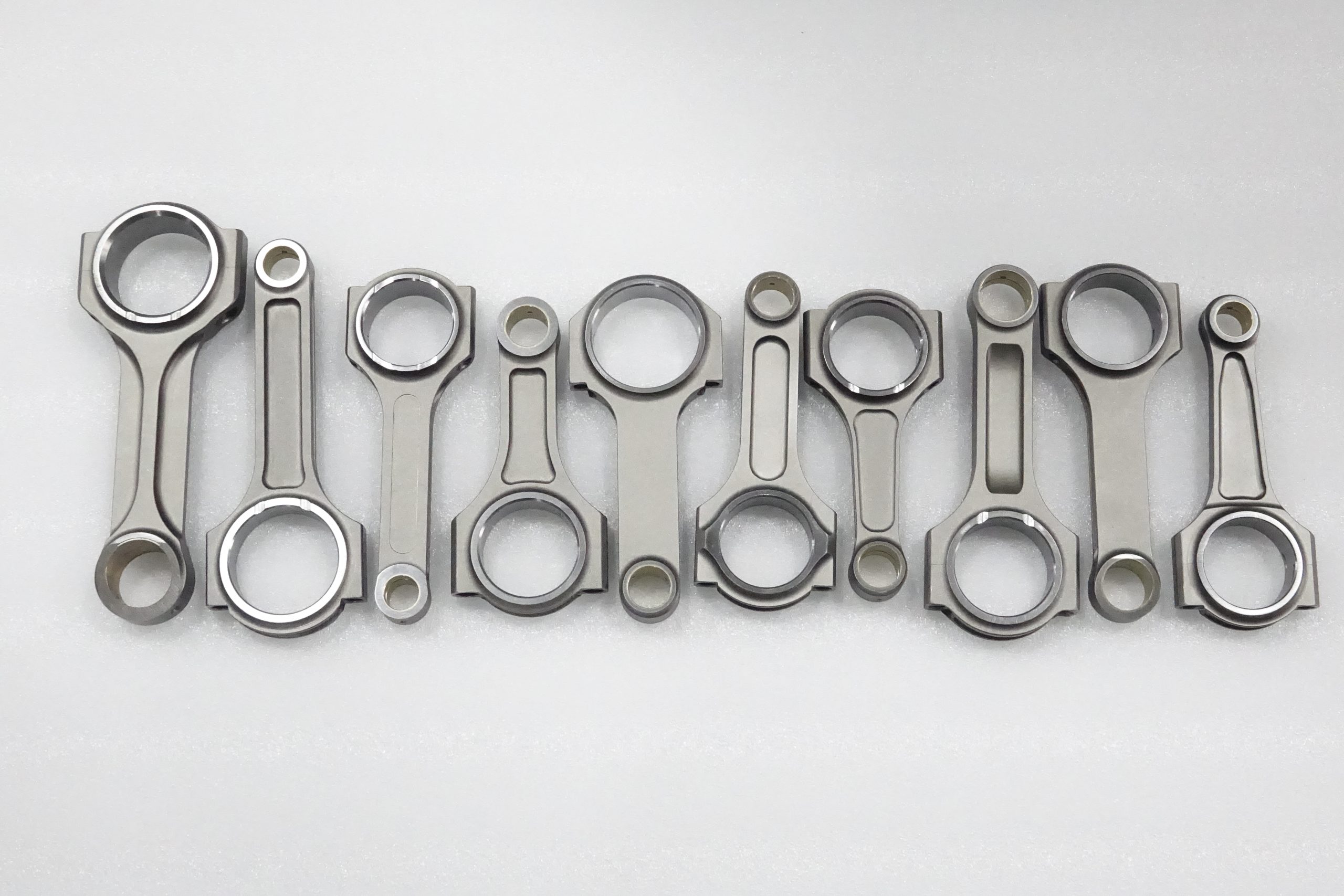

BMW 135mm Connecting Rods: Elevate Your Engine Performance with Precision

When it comes to enhancing the performance of your BMW engine, selecting the right components is essential. One such critical component is the connecting rod. This article will focus on BMW 135mm connecting rods and how they can improve your engine’s power and reliability. The Importance of BMW 135mm Connecting Rods Connecting rods play a crucial role in transforming the linear motion of pistons into rotational motion for the crankshaft. Upgrading to high-performance BMW 135mm connecting rods offers several benefits: Increased strength and durability: High-quality connecting rods can withstand the stress and strain of high-performance driving conditions, reducing the risk of engine failure. Improved engine performance: Upgraded connecting rods can enhance torque and horsepower, allowing your engine to operate more efficiently and responsively. Extended engine life: By investing in top-notch BMW 135mm connecting rods, you can potentially prolong the lifespan of your engine and reduce maintenance costs. Chinese FeDa Brand: